Model:AT-13 (Poland Customed machine)

1.machine suitable for PVC PET clear boxes crease and die cut

2. machine with high Frequency system with soft line crease

3.machine working table size 700*500 mm.

Plastic PVC boxes crease and die cut Machine

Model:AT-13(Poland Customed Machine)

Machine Features

Machine working veido

1: PVC PET Roll material--Crease and die cut -- Rewinding waste material

2: Suitable material: PVC APET rolls material.

3: Heating by oil and electric, Stable and save power.

4: HF heat die cut, the suitable soft line without any white or broken.

5: Mould made by normal wooden board with cutter, not special material mould.

6: 100% connect with working board without any medium.

7: Plastic Boxes line will not break.

8: Ensuring save worker source, Double-roller loading for automatic production.

| Machine Mode | AT-13 |

| Voltage | 380V 3 Phases 50HZ |

| Output Power | 10 KW |

| Max Crease Pressure | 45T |

| Air Compressor needed | 0.6 MPA |

| Working Frequency | 27.12 MHZ |

| Suitable Material | PVC PET APET RPET GAG |

| Crease Board Size | 700*500 mm |

| Roll material width | 700 mm |

| Machine Speed | 10-15 times/minute |

| Machine Size | 5600*2200*2270mm(L*W*H) |

Machine working process

1. roll material loading ,Max roll PVC PET material weight:100kg,Max diameter is 500mm with air shaft.

![MVI_8207[00_00_43][20151020-104839-8] MVI_8207[00_00_43][20151020-104839-8]](http://m.etoden.net/resource/images/b9d431e01bad4be7b81910e4574f9316_8_copy.bmp)

![MVI_8207[00_00_58][20151020-104854-9] MVI_8207[00_00_58][20151020-104854-9]](http://m.etoden.net/resource/images/b9d431e01bad4be7b81910e4574f9316_10_copy.bmp)

2. HF die cutting working head ,table size is 700*500 mm .machine working with High frequency system for boxes line soft crease.

3. Delivery system ,taking out the finished boxes shape by hand ,and waste plastic material will automatic rewinding .

4. Machine using mold: normally wooden die cut mold.

5.Operation panel display+PLC touch screen

6.Urgent stop button for safety operation

Machine working vedio :

youtube link:(long and clear vedio ,90% user choose)

PVC material working on that machine : https://www.youtube.com/watch?v=d-J5z_avCQ0

PET material working on that machine: https://www.youtube.com/watch?v=LtoueAGJDlg

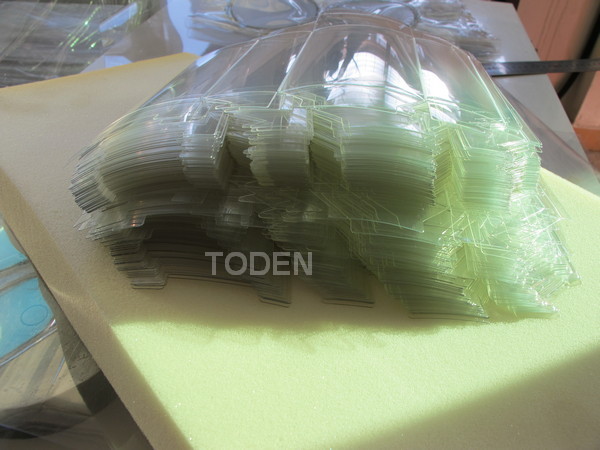

Sample made by this machine

any further quetions contact with us ,24 hours online service.