Model:AT-11

1. one worker operate the machine.

2. Two tables continues working.

3. one machine suitable for PVC PET sheet material.

Plastic boxes PVC PET sheet Crease and die Cut Machine

Model:AT-11

Machine Features

Machine working vedio:

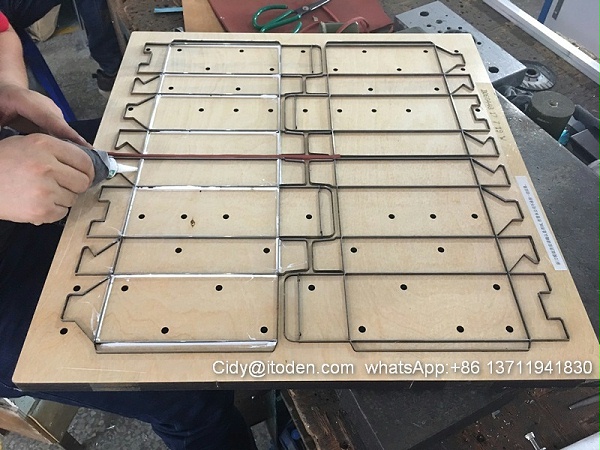

2.Mold Change less than 10 minutes with fast changing mold device.

3.High Sensitive anti-sparker 5557 from America can check the over-current, Ensuring reduce the damage between mold and material.it can automatic cut off the high frequency current by the time of sparking.

4.Mold and board without any medium ensuring plate 100% flatten.

5.Plastic boxes soft line will not easy break or white ,welcome to checking and testing

Machine parameter

| Machine Mode | AT-11 |

| Voltage | 380V 3 Phases 50HZ |

| Output Power | 15 KW |

| Max Crease Pressure | 40T |

| Air Compressor needed | 0.6 MPA |

| Working Frequency | 27.12 MHZ |

| Suitable Material | PVCPET APET RPET GAG |

| Crease Board Size | 850* 700 mm |

| material size | 790*640 mm |

| Machine Speed | 300-400 pieces/hour |

| Machine size | 2380*1300*1990 mm (L*W*L) |

Machine working vedio

Machine working Process:

1.Prepare the raw material ,sheet form ,PVC PET rigid material for boxes making .it should be suitable sheet size ,PVC PET transparent one or the prined material ,both can be using on that machine ,model AT-11

Printed sheet

Transparent clear sheet

2.Customer also need prepare two table for putting raw material and finished die cut sheet. Worker left hand in ,and worker right hand out. that will be faster speed .

![AT-11[00_00_05][20200805-103419] AT-11[00_00_05][20200805-103419]](http://m.etoden.net/resource/images/d508158a5e4e476987c4a376dc57f7fa_12_copy.png)

3.Machine up boad is 850*700 mm ,that means the working table is 850*700 mm ,the mold also need some area for locking it on machine .so effective max boxes size is :790*640 mm.

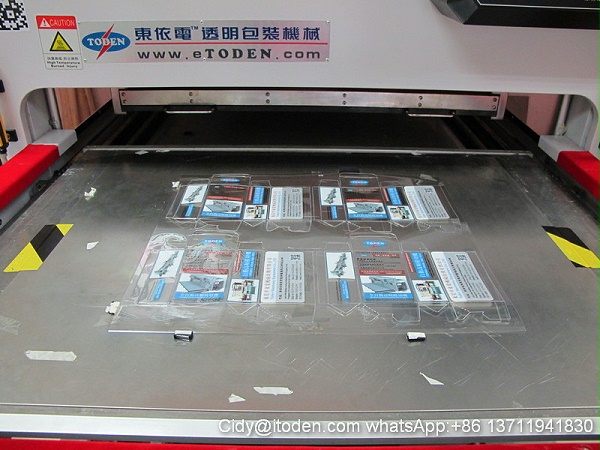

4.Ensuring the machine productivity ,it can putting many boxes in one mold according to the boxes size and machine output pressure.

5.Machine has two table continues working ,Manual model: using for testing ,or several sample die cut ,table working by touch the button of start ;Automatic Model,using for mas production during big order .no need button control, PLC counting the working time ,and setting the working time on PLC.

![AT-11[00_01_07][20200805-103545] AT-11[00_01_07][20200805-103545]](http://m.etoden.net/resource/images/d508158a5e4e476987c4a376dc57f7fa_16_copy.png)

6.The key point : AT-11 Plastic boxes PET PVC Sheet crease and die cut machine with high frequency system .the system can make the boxes folding line soft ,and no whtie ,no break after a long time folding ,it is easy forming 90 degree.and most high Value packages use the PET boxes by high frequency crease.

![AT-11[00_02_53][20200805-103809] AT-11[00_02_53][20200805-103809]](http://m.etoden.net/resource/images/d508158a5e4e476987c4a376dc57f7fa_22_copy.png)

die cut machine mold changing vedio: