Model:TD-MS-1020

1.Adopting aluminum alloy rack which is more light and solider

2.High stability

3.Two output line , high capacity

4.Fully Automatically , make outside earloop welding togther with mask producing process which can save labor , once non woven raw material in unwinding part use up , the machine can automatically stop .

Machine Picture view:

The full automatic face mask making machine adopts the servo and constant temperature control system controlled by PLC. The full-automatic mask realizes the flow process of full-automatic coil feeding, folding and pressing, nose rib feeding, mask forming, mask cutting, ear band feeding and Welding, finished product blanking. Using fully automatic face mask machine only one person can realize stable production, and the whole production process is fully automatic without any person Auxiliary work.

| Machine Model | TD-MS-1020 |

| Voltage | 220V .Single Phases 50 HZ |

| Output Power | 20K-2600W |

| Air compressor | 0.5-0.7 MPa,current flow about 300L/Min |

| Machine Speed | 80-100 Pieces/hour |

| Machine size | 6700*3500*2000 mm(L*W*H) |

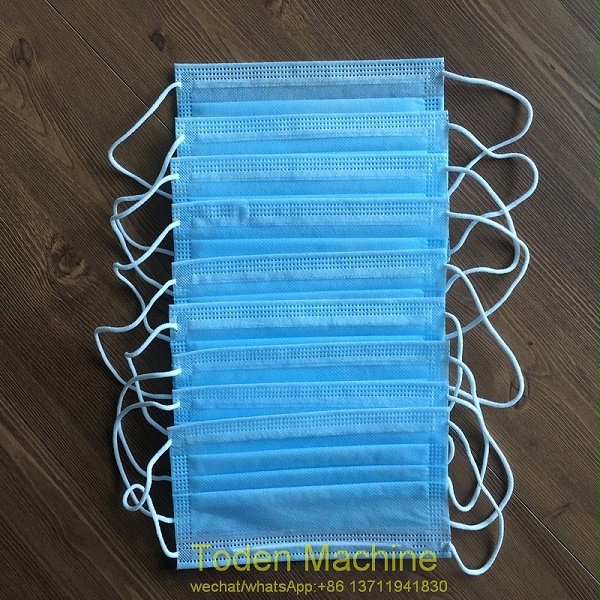

Sample finished by the Automatic Face Mask Machine

Machine working vedio: