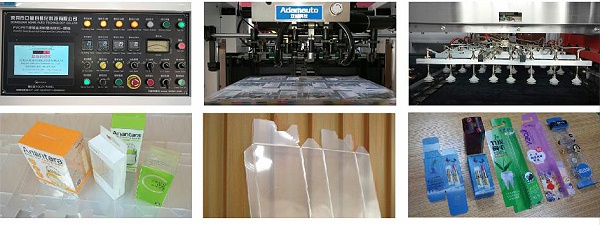

Machine model:TD-850AR

1. Automatic Plastic boxes high frequency soft line crease and die cut Machine (Stamping. soft line Crease、 Die cut. Stacking)

2. Single pieces sheet automatic feeding Unit

3. fast loading PET sheet device

one: Automatic Plastic boves high frequency soft line crease and die cut Machine (Stamping. Crease、 Die cut. Stipping. Stacking)

two: Single pieces sheet automatic feding Unit

three: Multi special sheet row Unit

four: Servo motor drives the horizontal precisions location double chain row

five: An independent controlled high frequency generator

six: Hydraulic pressure control high frequency soft line creasing Unit

seven: Hydraulic pressure control hot die cutting Unit

eight: servo driven suction cup stacking materail Unit

Ten: Choosing online putting UV oil, stamping,tippingclean holes,or stacking function.

| Machine Model | AD-1050AR |

| Max Closing Force | 7500kg |

| Electrode-holder plate size | 780x1100mm |

| Working plate size | 800X 1100mm |

| Creasing Capacity | 30 linear meters(PET-0.35mm) |

| Max Closing Force | 80000 kg |

| Punch-holder plate size | 780X 1100mm |

| Working plate size | 800X 1100mm |

| Die cut Capacity | 30 linear meters(PET-0.35mm) |

| Max sheet size | 750X 1050 mm |

| Output power of Generator | 30 KW |

| Working Frequency | 27.12MHz士0.6% |

| Feeding Voltage | 380V3PH+N+G 50HZ(other voltages on request) |

| Compressed air pressure | 0.6 Mpa |

| Produced ltem | PVC,PETG ,PET-GAG,APET,PP(Soft Line crease Boxes) |

| Productivity | 600-1000 pieces/hour (PET 0.2-0.8mm) |

| Machine Size | 8000X4500x 2600mm |

| Machine Weight | 14.8Ton |