Machine model:A-1204

1.Ensure machine can working stable,machine case use the steel material

2.PLC mirco-computer controls the machine,Digital parameter setting,automatic output.

3.Easy operate with high efficiency by import servo system and magnetic braking system.

4.Function: Putting PE protection film ,cutting into 2-3 pieces ,static dealing,corona treatment, flatten ,cutting in to sheet.

Machine Picture view:

Machine working vedio:

1. Machine suitable for PVC PET ,APET ,PETG rigid film.

2. Machine has flatten and cutting function.

3. Max width :1200 mm. 4 oil cylinder heating for flatten

4. mainly customer is the material supplier.

| Machine Model | A-1204 |

| Voltage | 380V .3 Phases 5 line ,60HZ |

| Output Power | 10KW |

| Max raw roll material diameter | 500 mm |

| Max width of roll material | less than 1100 mm |

| Material thickness | 0.18-1.0 mm |

| Precision | ≤ ±0.25 mm |

| Heating Cylinder | 4 cylinders |

| Air compressor needed | 0.6 MPA, 350l/mi |

| Machine speed | 30 m/minute |

| Machine size | 6200*1800*1300 mm(L*W*H) |

Machine working vedio:

Machine working Process:

1.Roll raw material loading, one or two loading roll both ok .standard only one .Inner core size is 74 mm.(this is China standard,some other size like 6'',it can be customed ).

![IMG_6894[20201109-102651] IMG_6894[20201109-102651]](http://m.etoden.net/resource/images/ca93e35f85a44c0c82e7037a8bbca568_2_copy.png)

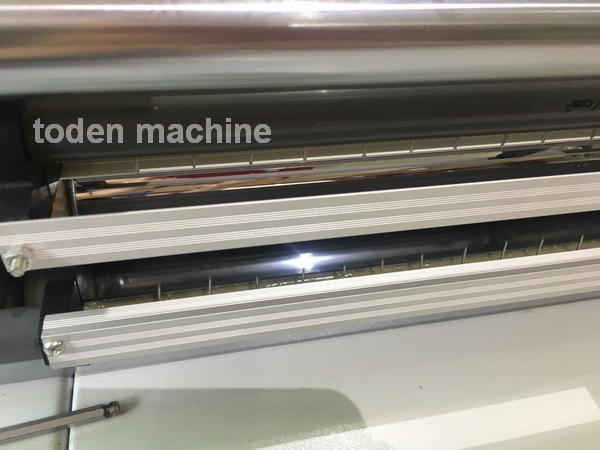

2. Four cylinder for flatten material function, Cylinder length is 1200 mm ,the effective working length is about 1150 mm .we need keep space for two side edge.

![IMG_6894[00_00_08][20201109-102703] IMG_6894[00_00_08][20201109-102703]](http://m.etoden.net/resource/images/ca93e35f85a44c0c82e7037a8bbca568_4_copy.png)

3.PE film lamination function ,we usually call it as Putting Protection film in case of scratching.

4.Static dealing ,this device can not totaly remove all static ,it is just reduce some of static .

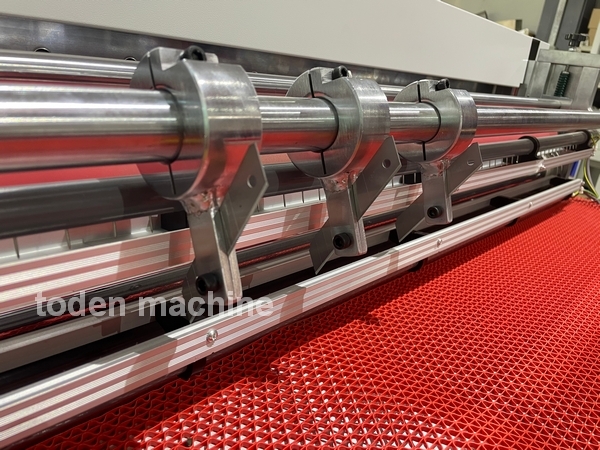

5.Slitting Device,simple device for sheet slitting.

6.Finished sheet ,max 1000 mm length.

![IMG_6894[00_00_22][20201109-102731] IMG_6894[00_00_22][20201109-102731]](http://m.etoden.net/resource/images/ca93e35f85a44c0c82e7037a8bbca568_16_copy.png)

normally sheet size production

![PNNT8611[00_00_05][20201109-103902] PNNT8611[00_00_05][20201109-103902]](http://m.etoden.net/resource/images/ca93e35f85a44c0c82e7037a8bbca568_14_copy.png)