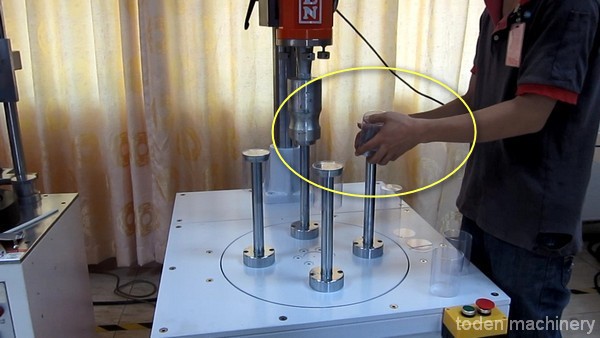

ultrasonic welding machine adopt 4 pillar with circle running .

the bottom welding by ultrasonic system,welding area without white ,and beautiful.

the ultrasonic bottom welding machine for different diameter ,height ,and material.the welding can be what you like .the machine easy operation with high quality product making .it is not only for PVC cylinder bottom welding machine ,it also for other material ultrasonic welding.

Ultrasonic bottom welding machine application:PVC clear cylinder welding ,transparent tube bottom welding .the cylinder suitable for candy packages,gift .and gift boxes making .it is widely use plastic packages line.

Machine Picture view:

1. Machine suitable for PVC cylinder bottom ultrasonic welding.

2. Machine has four welding position working continues.

3. One machine suitable for different sixes cylinder producing

4. ultrasonic welding cylinder tube bottom is strong ,and without any glue.

| Machine Model | A-608 |

| Voltage | 220V Single Phase 50HZ |

| Output Power | 2.5KW |

| Cylinder diameter | 40-190 mm |

| Cylinder length | less than 350 mm |

| Material thickness | 0.18-0.4 mm |

| Machine speed | 500-800 pieces/hour, 100 mm as sample |

| Function | bottom by ultrasonic welding system |

| Machine size | 980*880*1750 mm(L*W*H) |

Machine working vedio:

Machine working steps

1. customer need prepare the suitable size of round sheet,and curled round tube ,which already curled on one side at least .

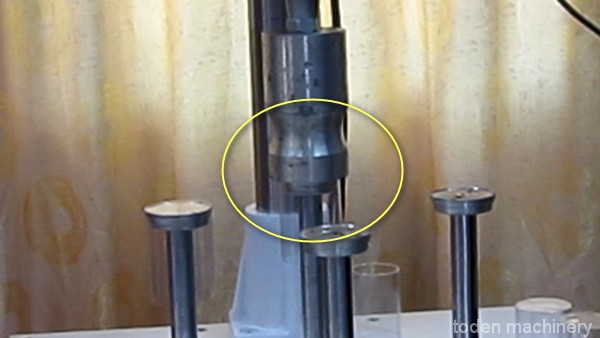

2. Prepare the related mold ,one up mold + 4 pcs down mold.

3. first putting the PVC round sheet upon the mold.

4. than putting the curled tube upon the mold

5. start the machine as manual working model ,up mold will going down ,and touch the bottom mold ,ultrasonic welding at the same time.

6. Manual taking off the finished PVC cylinder tube ,and checking the welding area to adjusting the up and down mold level.

7. than set machine as automatic model ,working circle.

Ultrasonic bottom welding machine down mold

PVC cylinder welding machine up mold-Horn

PVC cylinder bottom welding Sample